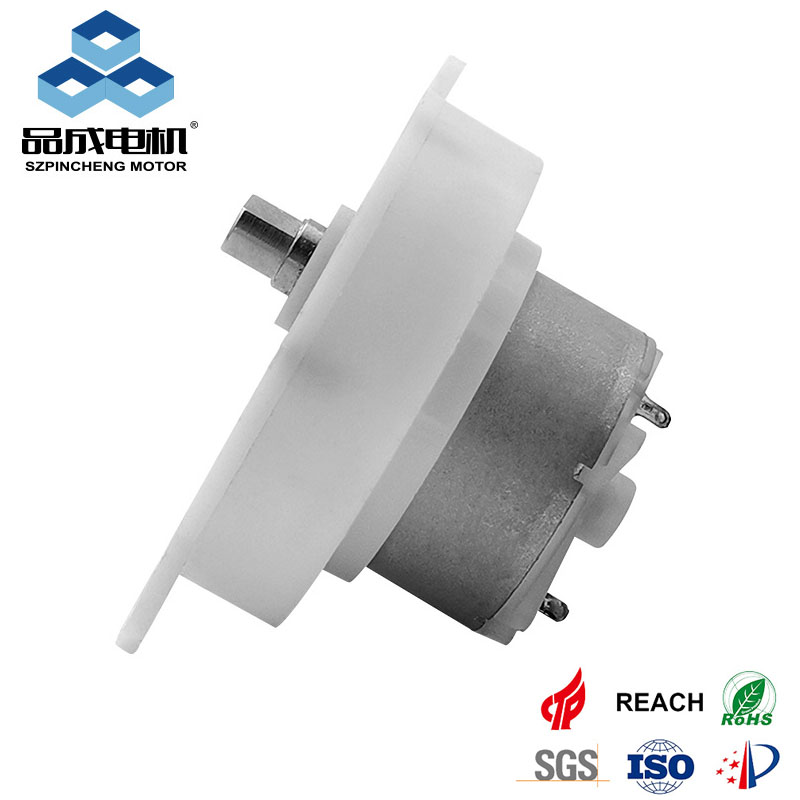

Custom Small DC Gear Motors | Manufacturer & Supplier - Pincheng

Pincheng offers high-performance Small DC Gear Motors designed for precision applications. Customizable options available to meet your specific needs.

Why Choose Pincheng Small DC Gear Motors

Pincheng's Small DC Gear Motor is designed to deliver high performance while offering customization options that make it perfect for a wide range of applications. With a focus on precision, durability, and efficiency, our motors are ideal for industries such as robotics, automation, medical devices, and consumer electronics. Pincheng provides tailored solutions to ensure that every customer receives the most suitable product for their needs.

Choose Your Small DC Gear Motor

Pincheng's Small DC Gear Motors are trusted by customers worldwide for their high performance, long lifespan, and customization services. No matter your industry, we are equipped to provide you with the best motor solutions. If you have any needs or questions, please feel free to contact us. We look forward to working with you to enhance your business competitiveness.

Best DC Gear Motor Manufacturer and Exporter In China

We can provide the best price and technical support for commercial projects.

The Working Principle of Dc Geat Motor

Pincheng can offer the customized parameter

- The DC motor inside the DC gear motor converts electrical energy into mechanical rotary motion through the interaction of magnetic fields. When direct current is applied to the motor's terminals, the inductor (coil) inside creates a magnetic field that interacts with the fixed magnets on the shaft, generating torque and causing the shaft to rotate.

- The gearbox, also known as a reduction gear, is connected to the output shaft of the DC motor. It consists of gears with different numbers of teeth. The gearbox reduces the high-speed output of the DC motor to a lower speed while significantly increasing the torque. This is achieved by the mechanical advantage provided by the gear ratio, which is the ratio of the number of teeth on the driving gear to the number of teeth on the driven gear.

The Dc Gear motor Advantages

High Torque at Low Speeds:

DC gear motors are designed to provide high torque output even at relatively low rotational speeds. This makes them suitable for applications where a large amount of force is required to move or operate a load, such as in conveyor systems, lifts, and heavy machinery.

Precise Speed Control:

They offer precise control over the rotational speed. By adjusting the voltage or current supplied to the DC motor, the speed of the motor and, consequently, the output speed of the gear motor can be accurately regulated. This is crucial in applications where specific speed requirements are necessary, like in robotics, medical equipment, and automated manufacturing processes.

Compact and Lightweight Design:

DC gear motors are often relatively small and lightweight compared to other types of motors with similar torque capabilities. Their compact size makes them easy to integrate into various devices and systems, saving space and reducing overall weight, which is beneficial for applications with limited space or weight restrictions, such as in portable equipment, small robots, and electric vehicles.

Good Starting and Stopping Capabilities:

They can start and stop quickly and smoothly, allowing for efficient operation in applications that require frequent start-stop cycles, such as in electric vehicles, where rapid acceleration and deceleration are necessary.

What are dc gear motor Applications for?

Industrial Automation:

Widely used in conveyor belts, production line equipment, packaging machinery, and other automated industrial processes where precise control of speed and torque is essential for efficient and reliable operation.

Robotics:

Play a vital role in robotic systems, providing the necessary power and precise motion control for robot joints, grippers, and other moving parts, enabling robots to perform tasks with accuracy and repeatability.

Medical Equipment:

Found in various medical devices such as infusion pumps, dialysis machines, surgical tools, and hospital beds, where accurate speed and torque control are critical for patient safety and the proper functioning of the equipment.

Automotive Industry:

Used in electric vehicles for driving wheels, power steering systems, windshield wipers, and other automotive applications that require high torque and reliable performance.

Home Appliances:

Incorporated into appliances like washing machines, dryers, vacuum cleaners, and power tools to provide the necessary power and controlled motion for their operation.

Pincheng DC gear motors mainly have the following types

Brushed DC Gear Motors:

This is the most common type. It features brushes that make contact with the commutator on the motor shaft. They offer a good balance of performance, cost, and ease of control, and are widely used in various applications due to their relatively simple structure and reliable operation.

Brushless DC Gear Motors (BLDC):

These motors utilize electronic commutation instead of brushes, which leads to higher efficiency, lower maintenance requirements, and longer lifespans. They are more advanced in technology and are often used in applications where high efficiency and reliability are required, although they tend to be more expensive than brushed DC motors.

Planetary Gear Motors:

These motors employ a planetary gear arrangement, which consists of a central sun gear, multiple planet gears, and an outer ring gear. This design offers high torque output in a compact package and provides smooth and precise operation. They are often used in applications requiring high precision and smooth motion, such as robotics and automation systems.

Worm Gear Motors:

These motors utilize a worm gear and a worm wheel configuration. They provide exceptionally high torque reduction and self-locking capabilities, meaning the motor can hold its position without the need for additional braking mechanisms. They are well-suited for low-speed, high-torque applications such as lifts, winches, and conveyor systems where holding the load in place is crucial.

Customization Options

Pincheng understands that each customer's needs are unique, so we offer a range of customization services to help you choose the best small DC gear motor for your application.

We can provide motors with varying voltage and torque to suit your application needs. Whether for low-power devices or high-load applications, we offer the right solution.

We offer different gear ratios to help adjust the motor's output speed and torque, optimizing device performance.

To suit different working environments, we offer a variety of housing materials, including plastics and metals, with varying corrosion resistance and durability.

We offer a variety of connectors and wiring options to ensure seamless compatibility with your system.

Tailor Your Perfect DC Geat Motor Today!

If you are interested in our products or customization services, feel free to contact us. Our team is ready to assist you and provide tailored solutions.