Key Parameters to Consider When Choosing a Miniature Gear Motor

Miniature gear motors are compact powerhouses that combine electric motors with gearboxes to deliver high torque at low speeds. Their small size and versatility make them ideal for a wide range of applications, from medical devices to robotics. However, selecting the right miniature gear motor requires careful consideration of several key parameters to ensure optimal performance and longevity.

1. Speed and Torque Requirements:

Speed (RPM): Determine the desired output speed of your application. Gear motors reduce the motor's high speed to a lower, more usable speed.

Torque (oz-in or mNm): Identify the amount of rotational force required to drive your load. Consider both starting torque (to overcome inertia) and running torque (to maintain motion).

2. Voltage and Current:

Operating Voltage: Match the motor's voltage rating to your power supply. Common voltages include 3V, 6V, 12V, and 24V DC.

Current Draw: Ensure your power supply can provide sufficient current to meet the motor's demands, especially under load.

3. Size and Weight:

Dimensions: Consider the available space for the motor in your application. Miniature gear motors come in various sizes, from a few millimeters to several centimeters in diameter.

Weight: For weight-sensitive applications, choose a motor with a lightweight design.

4. Gear Ratio:

Ratio Selection: The gear ratio determines the speed reduction and torque multiplication. Higher ratios provide greater torque but lower speed, while lower ratios offer higher speed but less torque.

5. Efficiency and Noise:

Efficiency: Look for motors with high efficiency ratings to minimize power consumption and heat generation.

Noise Level: Consider the acceptable noise level for your application. Some motors operate more quietly than others.

6. Duty Cycle and Lifespan:

Duty Cycle: Determine the expected operating time (continuous or intermittent) and choose a motor rated for the appropriate duty cycle.

Lifespan: Consider the expected lifespan of the motor under your operating conditions.

7. Environmental Factors:

Temperature Range: Ensure the motor can operate within the expected temperature range of your application.

Ingress Protection (IP) Rating: If the motor will be exposed to dust, moisture, or other contaminants, choose a model with an appropriate IP rating.

8. Cost and Availability:

Budget: Set a realistic budget for your motor, considering both initial cost and long-term operating expenses.

Availability: Choose a motor from a reputable supplier with reliable stock and lead times.

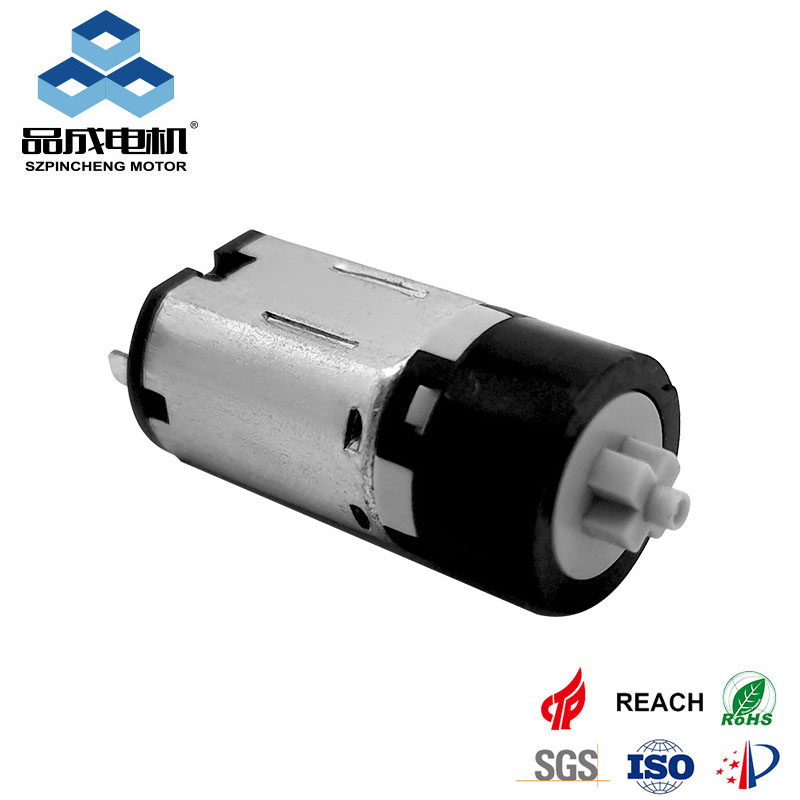

Introducing Pincheng motor: Your Trusted Partner for Miniature Gear Motors

Pincheng motor is a leading manufacturer of high-quality miniature gear motors, offering a wide range of products to meet diverse application needs. Our motors are renowned for their:

Compact Size and Lightweight Design: Ideal for space-constrained applications.

High Efficiency and Low Noise: Ensuring smooth and quiet operation.

Durable Construction and Long Lifespan: Built to withstand demanding environments.

Customization Options: Tailored to meet specific requirements.

Explore our featured miniature gear motor series:

PGM Series: Planetary gear motors offering high torque and efficiency in a compact package.

WGM Series: Worm gear motors providing excellent self-locking capabilities and low noise operation.

SGM Series: Spur gear motors featuring a simple design and cost-effective solution for various applications.

Visit our website or contact us today to learn more about our miniature gear motors and find the perfect solution for your application.

Remember: Selecting the right miniature gear motor is crucial for optimal performance and reliability. By carefully considering the key parameters outlined above and partnering with a trusted manufacturer like Pinmotor, you can ensure your application runs smoothly and efficiently for years to come.

you like also all

Read More News

Post time: Feb-10-2025