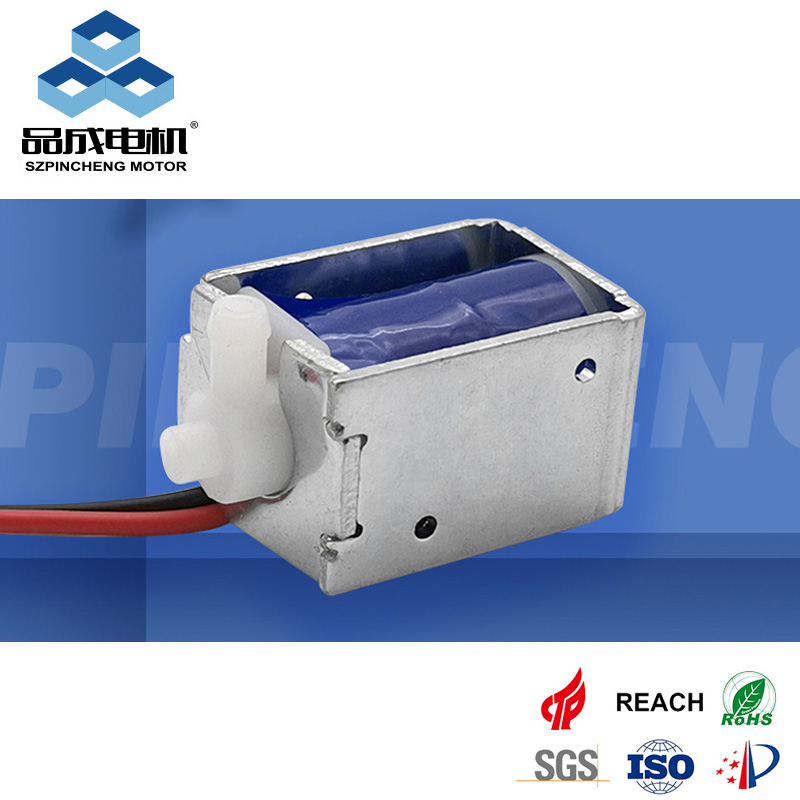

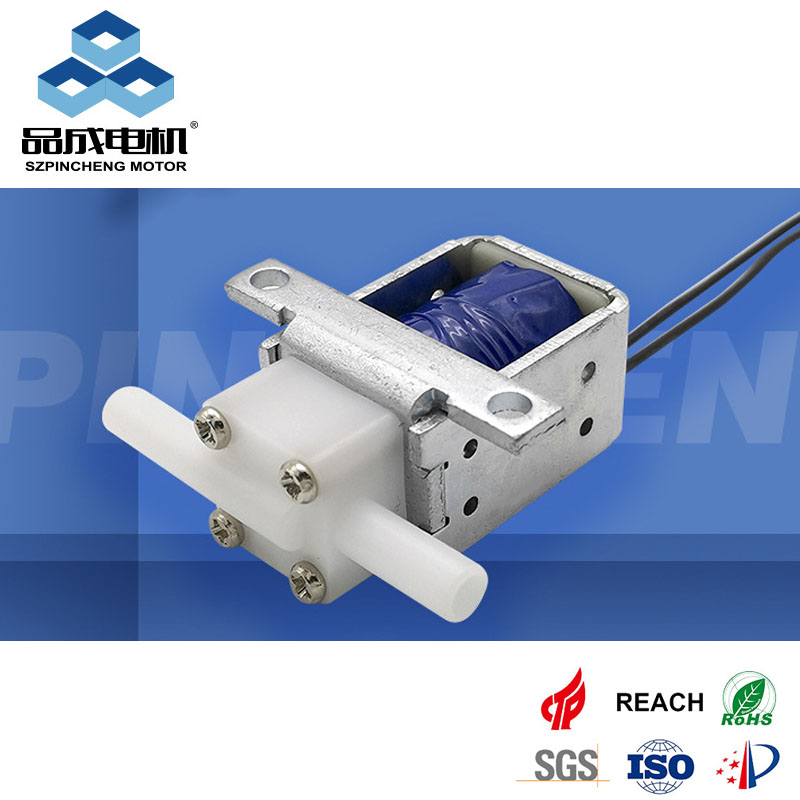

Pincheng Custom DC Solenoid Valve Manufacturer in China

High-Quality, Durable, and Reliable Solenoid Valves for Your Business

About Pincheng DC Solenoid Valve

Pincheng is a leading manufacturer of high-quality DC solenoid valves, designed to provide efficient and reliable flow control solutions for various industrial applications. Our valves are engineered for precision and long-lasting performance in systems that require precise fluid regulation. With our expertise and commitment to quality, Pincheng has become a trusted partner for businesses seeking reliable solenoid valves.

Choose Your DC Solenoid Valve

At Pincheng, quality is our top priority. Our DC solenoid valves are tested to meet international standards and certifications. We are committed to delivering products that meet the highest levels of quality, performance, and reliability.

Best Dc Solenoid Valve Manufacturer and Exporter In China

We can provide the best price and technical support for commercial projects.

Common Types of Solenoid Valves

Electronic valves, also known as solenoid valves, are electromechanical devices that control the flow of fluids (liquids or gases) . Here are some common types:

DC solenoid valves Working Principle

Direct-acting Electronic Valves:

When energized, the electromagnetic coil generates a magnetic force that directly lifts the open part from the valve seat, opening the valve. When de-energized, the magnetic force disappears, and the spring presses the open part onto the valve seat, closing the valve. They can work under vacuum, negative pressure, or zero pressure, but the diameter is generally not more than 25 mm.

Step-by-step Direct-acting Electronic Valves:

It combines the principles of direct-acting and pilot-operated valves. When there is no pressure difference between the inlet and outlet, after energization, the electromagnetic force directly lifts the pilot small valve and the main valve closing part in sequence to open the valve. When the inlet and outlet reach the starting pressure difference, after energization, the electromagnetic force acts on the pilot small valve, the pressure in the lower chamber of the main valve rises, and the pressure in the upper chamber drops, so that the main valve is pushed upward by the pressure difference. When de-energized, the pilot valve uses spring force or medium pressure to push the closing part downward to close the valve. They can operate under zero pressure difference, vacuum, or high pressure, but they have higher power requirements and must be installed horizontally.

Pilot-operated Electronic Valves:

When energized, the electromagnetic force opens the pilot hole, the pressure in the upper chamber drops rapidly, and a pressure difference with a lower upper part and a higher lower part is formed around the open part. The fluid pressure pushes the open part upward to open the valve. When de-energized, the spring force opens the pilot hole, the inlet pressure enters the chamber through the bypass hole, and a pressure difference with a lower lower part and a higher upper part is formed around the closing part. The fluid pressure pushes the open part downward to close the valve. They have small volume, low power, and a relatively high upper limit of fluid pressure range, and can be installed arbitrarily (customization is required) but must meet the fluid pressure difference condition.

By Valve Channel Number

Two-way Electronic Valves:

Control the on-off of a single flow path, allowing or blocking the flow of fluid in one direction.

Three-way Electronic Valves:

Have three ports and are used to control the flow direction of fluid, such as diverting or mixing the flow.

Four-way Electronic Valves:

With four ports, they are often used in more complex fluid control systems, such as controlling the movement of double-acting cylinders.

Applications of DC Solenoid Valves

Our DC solenoid valves are widely used in various industries, including:

Automated Systems:

For precise fluid regulation in robotics and industrial automation.

Fluid Control Systems:

In water treatment plants, HVAC systems, and chemical processing.

Medical Devices:

Ensuring accurate fluid delivery in diagnostic and therapeutic equipment.

Agriculture:

Used in irrigation systems to regulate water flow efficiently.

Customization Options

We understand that every application has its unique requirements. That’s why we offer comprehensive customization options for our DC solenoid valves. Our team will work with you to create the perfect solution based on your specifications.

Size & Dimensions: Custom sizes to fit your installation space and application needs.

Material Selection: Choose from a variety of materials based on your environmental and performance requirements.

Voltage & Current: Custom voltage and current configurations to match your system specifications.

Actuation Type: Options for direct current, alternating current, or pulse-actuated valves based on your control system.

Tailor Your Perfect Micro Air Pump Today!

Contact Pincheng now to customize airflow, materials, and design for your unique needs. Let’s create a solution that fits your application perfectly!